Building or Remodeling on the Coast?

Here’s What to Consider When Selecting Your Hardware:

Photo by Ivana Cajina on Unsplash

Design, finish, size, texture, weight, patina, function, price, and durability – we regularly study these factors when selecting hardware to fit your clients’ vision and your standards. When your project is at the coast, however, we add another element to the checklist: material corrosiveness.

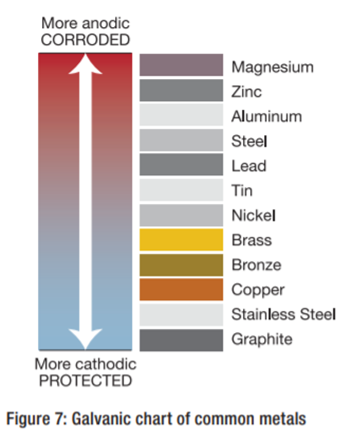

Salty air and water can accelerate the degradation of metals, so it’s important to consider the composition and maintenance of your hardware when exposed to these elements. The damage to metals is caused by sodium chloride – these particles become oxygenated and airborne when waves turn into mist, which then travels and, if it lands on metal, begins to deteriorate it 1Britannica: Corrosion Resistance. Salty air can corrode metal much faster than inland air, and may have an effect on metal 5-10 miles away – this means corrosion is not a concern isolated to buildings directly on a beach 2FEMA Document. According to FEMA, factors that influence corrosion rate include “proximity to shoreline, high temperature, high humidity, elevation, and exposure class.” The chart below outlines various metals’ ability to withstand salty settings.

What can you do to keep hardware looking good and performing well for as long as possible?

- Routine maintenance, according to the hardware manufacturer, will help prevent the accumulation of salt, increasing the longevity of your door and cabinet hardware. Keep your hardware dry and clean You can also protect the finish on hardware by applying a non-caustic wax, carnauba wax.

- Choose hardware made of a material that weathers salty air better.

COMMON HARDWARE MATERIALS TO AVOID

Carbon Steel – Requires a protective coating.

Aluminum

Nickel

Brass – As an alloy of copper that contains zinc, brass is more susceptible to corrosion than pure copper. This is due to the high percentage of zinc that it contains – in this atmosphere, the zinc may corrode in a way that leaves a weakened copper shell – this is called dezincification.

HARDWARE MATERIALS TO CONSIDER USING

PVD – PVD (physical vapor deposition), also known as thin-film coating, is a process in which a solid material is vaporized in a vacuum and deposited onto the surface of a part. These coatings are not simply metal layers. Instead, compound materials are deposited atom by atom, forming a thin, bonded, metal or metal-ceramic surface layer that greatly improves the appearance, durability, and/or function of a part or product. If you want a brass look without the corrosion factor, PVD is the best option.

Zinc Coating – Zinc galvanizes metal, meaning it stops the reaction between iron, oxygen, and water, working to delay rust and corrosion. 3Britannica: Brass

Stainless Steel – The most common choice for coastal buildings, this material fares much better in ocean air than other metals such as aluminum.

- However, 304 stainless steel – the most-used type – is more prone to corrosion and stains than its counterpart, 316 stainless steel, which withstands corrosion well due to the inclusion of a small percentage of molybdenum. 4Britannica: Stainless Steel

- Smooth finishes on stainless steel help boost corrosion resistance.

- Stay away from joining stainless steel with other metals, because this combination can increase the corrosion rate.

Bronze – While, like brass, bronze is also a copper alloy, it withstands coastal conditions well due to its lack of zinc and inclusion of tin 5Britannica: Corrosion Resistance.

FINDING THE RIGHT HARDWARE FOR YOUR PROJECT

At National Builders Hardware, we work with our suppliers to ensure that we can provide you with the best selections of hardware that will stand up to a coastal setting. Our decorative and architectural hardware experts have extensive experience in assisting our clients in determining the most suitable materials for your goals. That means we inquire about your project timeline, your design vision, and your customers’ intentions, budget, and preferences, to help you quickly see which choices will make the most sense to achieve an end result that is both beautiful and durable.

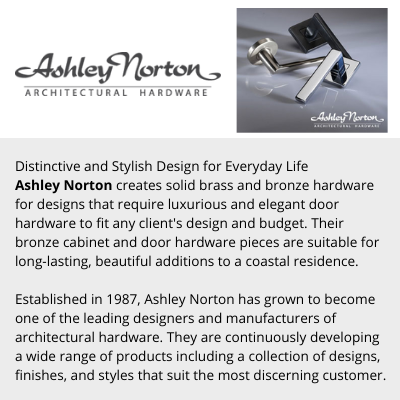

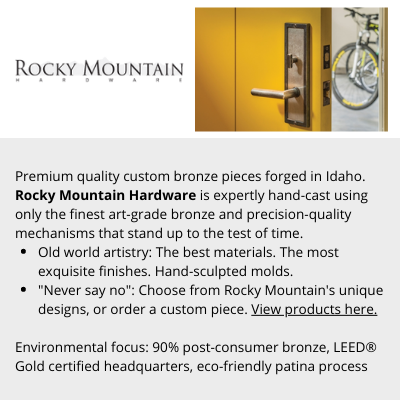

Here are a few hardware manufacturers whose catalogs we might suggest you begin with when considering your door and cabinet hardware options. Each maker offers an impressive selection of either stainless steel or bronze pieces:

Building or Remodeling on the Coast?

Here’s What to Consider When Selecting Your Hardware:

Photo by Ivana Cajina on Unsplash

Design, finish, size, texture, weight, patina, function, price, and durability – we regularly study these factors when selecting hardware to fit your clients’ vision and your standards. When your project is at the coast, however, we add another element to the checklist: material corrosiveness.

Salty air and water can accelerate the degradation of metals, so it’s important to consider the composition and maintenance of your hardware when exposed to these elements. The damage to metals is caused by sodium chloride – these particles become oxygenated and airborne when waves turn into mist, which then travels and, if it lands on metal, begins to deteriorate it 6Britannica: Corrosion Resistance. Salty air can corrode metal much faster than inland air, and may have an effect on metal 5-10 miles away – this means corrosion is not a concern isolated to buildings directly on a beach 7FEMA Document. According to FEMA, factors that influence corrosion rate include “proximity to shoreline, high temperature, high humidity, elevation, and exposure class.” The chart below outlines various metals’ ability to withstand salty settings.

What can you do to keep hardware looking good and performing well for as long as possible?

- Routine maintenance, according to the hardware manufacturer, will help prevent the accumulation of salt, increasing the longevity of your door and cabinet hardware. Keep your hardware dry and clean You can also protect the finish on hardware by applying a non-caustic wax, carnauba wax.

- Choose hardware made of a material that weathers salty air better.

COMMON HARDWARE MATERIALS TO AVOID

Carbon Steel – Requires a protective coating.

Aluminum

Nickel

Brass – As an alloy of copper that contains zinc, brass is more susceptible to corrosion than pure copper. This is due to the high percentage of zinc that it contains – in this atmosphere, the zinc may corrode in a way that leaves a weakened copper shell – this is called dezincification.

HARDWARE MATERIALS TO CONSIDER USING

PVD – PVD (physical vapor deposition), also known as thin-film coating, is a process in which a solid material is vaporized in a vacuum and deposited onto the surface of a part. These coatings are not simply metal layers. Instead, compound materials are deposited atom by atom, forming a thin, bonded, metal or metal-ceramic surface layer that greatly improves the appearance, durability, and/or function of a part or product. If you want a brass look without the corrosion factor, PVD is the best option.

Zinc Coating – Zinc galvanizes metal, meaning it stops the reaction between iron, oxygen, and water, working to delay rust and corrosion. 8Britannica: Brass

Stainless Steel – The most common choice for coastal buildings, this material fares much better in ocean air than other metals such as aluminum.

- However, 304 stainless steel – the most-used type – is more prone to corrosion and stains than its counterpart, 316 stainless steel, which withstands corrosion well due to the inclusion of a small percentage of molybdenum. 9Britannica: Stainless Steel

- Smooth finishes on stainless steel help boost corrosion resistance.

- Stay away from joining stainless steel with other metals, because this combination can increase the corrosion rate.

Bronze – While, like brass, bronze is also a copper alloy, it withstands coastal conditions well due to its lack of zinc and inclusion of tin 10Britannica: Corrosion Resistance.

FINDING THE RIGHT HARDWARE FOR YOUR PROJECT

At National Builders Hardware, we work with our suppliers to ensure that we can provide you with the best selections of hardware that will stand up to a coastal setting. Our decorative and architectural hardware experts have extensive experience in assisting our clients in determining the most suitable materials for your goals. That means we inquire about your project timeline, your design vision, and your customers’ intentions, budget, and preferences, to help you quickly see which choices will make the most sense to achieve an end result that is both beautiful and durable.

Here are a few hardware manufacturers whose catalogs we might suggest you begin with when considering your door and cabinet hardware options. Each maker offers an impressive selection of either stainless steel or bronze pieces:

Sources:

1. Britannica. (n.d.). Corrosion Resistance: Barrier Protection. Https://Www.Britannica.Com. Retrieved July 2021, from https://www.britannica.com/science/metallurgy/Corrosion-resistance

2. FEMA. (2019, June). Corrosion Protection for Metal Connectors and Fasteners in Coastal Areas. https://www.fema.gov/sites/default/files/2020-07/tb8-corrosion_protection_metal_connectors_coastal_areas.pdf.

3. The Editors of Encyclopaedia Britannica. (n.d.). Brass. Britannica. https://www.britannica.com/technology/brass-alloy.

4. The Editors of Encyclopaedia Britannica. (n.d.). Stainless Steel: Metallurgy. Https://Www.Britannica.Com. Retrieved July 2021, from https://www.britannica.com/technology/stainless-steel

Sources:

1. Britannica. (n.d.). Corrosion Resistance: Barrier Protection. Https://Www.Britannica.Com. Retrieved July 2021, from https://www.britannica.com/science/metallurgy/Corrosion-resistance

2. FEMA. (2019, June). Corrosion Protection for Metal Connectors and Fasteners in Coastal Areas. https://www.fema.gov/sites/default/files/2020-07/tb8-corrosion_protection_metal_connectors_coastal_areas.pdf.

3. The Editors of Encyclopaedia Britannica. (n.d.). Brass. Britannica. https://www.britannica.com/technology/brass-alloy.

4. The Editors of Encyclopaedia Britannica. (n.d.). Stainless Steel: Metallurgy. Https://Www.Britannica.Com. Retrieved July 2021, from https://www.britannica.com/technology/stainless-steel